Introduction

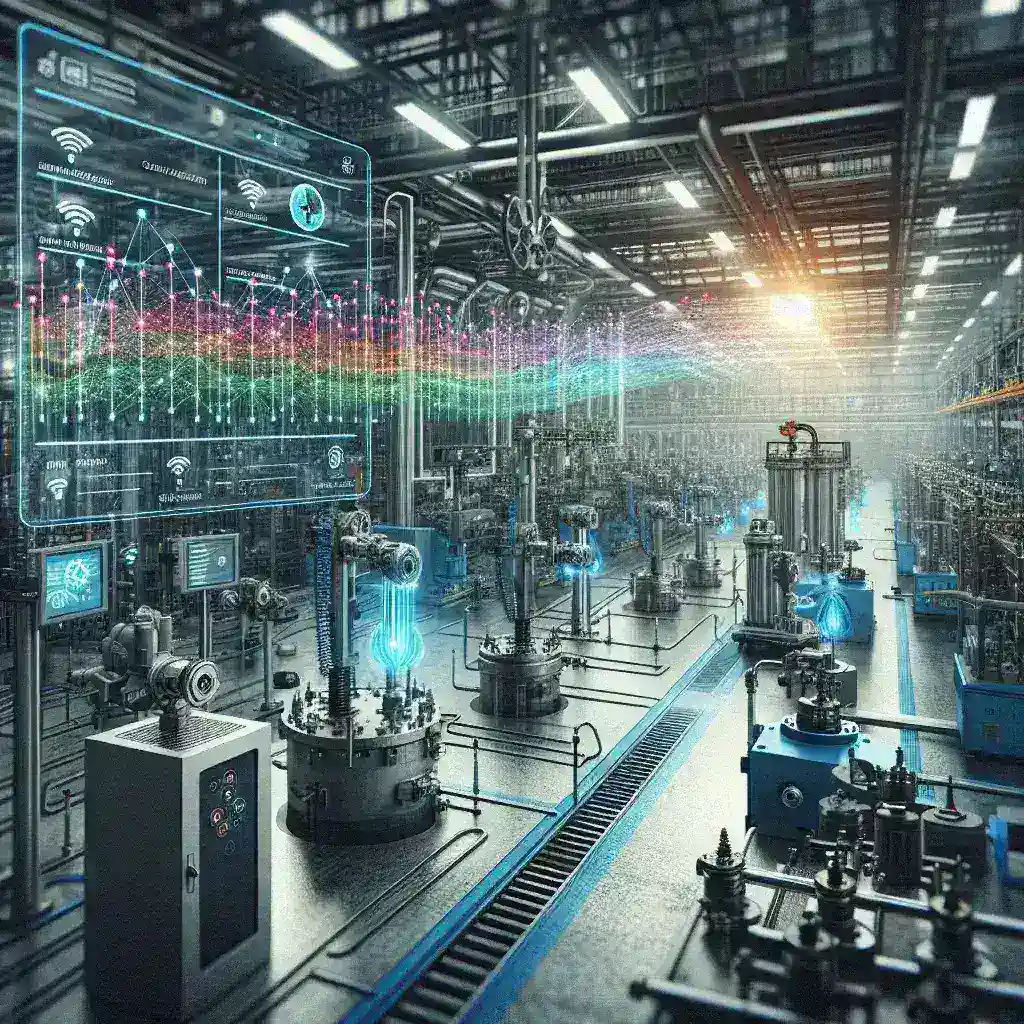

The Industrial Internet of Things (IIoT) has emerged as a powerful tool in transforming traditional manufacturing processes. Predictive maintenance, fueled by IoT, is not just a trend; it is rapidly becoming a cornerstone of operational efficiency in industrial environments. This article delves into the role of IoT in predictive maintenance for industrial machinery, examining its advantages, challenges, and future implications.

Understanding Predictive Maintenance

Predictive maintenance refers to the technique of predicting when equipment will fail so that maintenance can be performed just in time to address the issue without causing disruption to operations. Unlike reactive maintenance, which addresses problems after they occur, and preventive maintenance, which follows a fixed schedule, predictive maintenance leverages real-time data to optimize maintenance schedules based on actual equipment condition.

The Role of IoT in Predictive Maintenance

IoT devices collect vast amounts of data from machines via sensors that monitor variables such as temperature, vibration, and pressure. This data can be transmitted to a cloud-based system for analysis, helping maintenance teams forecast potential equipment failures. The integration of IoT in predictive maintenance offers several key advantages:

- Real-Time Monitoring: Continuous data streaming allows for immediate insights into the health of machinery.

- Data-Driven Decisions: Historical data analysis enables informed maintenance decisions, reducing downtime.

- Cost Efficiency: By predicting failures, companies can minimize unnecessary maintenance costs and extend equipment lifespans.

Real-World Example

General Electric (GE) has been at the forefront of implementing IoT for predictive maintenance. Their digital wind farm initiative uses sensors to track turbine performance and predict maintenance needs, which has resulted in a 10% increase in efficiency and significant cost savings.

Advantages of IoT-Driven Predictive Maintenance

1. Minimized Downtime: Machine failures can lead to costly production delays. IoT helps predict when maintenance is necessary, preventing unexpected breakdowns.

2. Improved Safety: Regular monitoring of equipment reduces the risk of accidents caused by malfunctioning machinery.

3. Enhanced Productivity: With machines running at optimal efficiency, overall productivity increases, allowing businesses to meet market demands effectively.

Challenges in Implementing IoT for Predictive Maintenance

Despite its numerous benefits, integrating IoT technology into predictive maintenance is not without challenges:

- Data Security: With an increase in data collection comes the risk of cyberattacks. Ensuring data privacy and security is paramount.

- Integration Costs: Initial setup costs for IoT infrastructure can be high, posing a barrier for smaller companies.

- Data Overload: Handling and analyzing the massive volumes of data generated can be overwhelming without the right tools.

Expert Insights

According to Dr. Alex Hussey, a leading researcher in IoT applications for manufacturing, “The ability to predict failures before they happen is not just a luxury but a necessity for staying competitive in today’s fast-paced market.”

The Future of IoT in Predictive Maintenance

The future of predictive maintenance appears bright with advancements in AI and machine learning enhancing IoT capabilities. As algorithms become more sophisticated, the accuracy of predictions will improve, facilitating even more proactive maintenance approaches. Moreover, with the rise of 5G technology, the speed and reliability of data transmission will further bolster IoT applications in this area.

Conclusion

In conclusion, the integration of IoT into predictive maintenance for industrial machinery is transforming how companies approach equipment management. By leveraging real-time data, organizations can enhance operational efficiency, reduce costs, and ultimately improve their bottom line. As technology continues to evolve, the impact of IoT on predictive maintenance is likely to grow, ushering in a new era of intelligent manufacturing.

For businesses looking to stay competitive, investing in IoT for predictive maintenance is not just an option—it is becoming a necessity.